RT 840 M

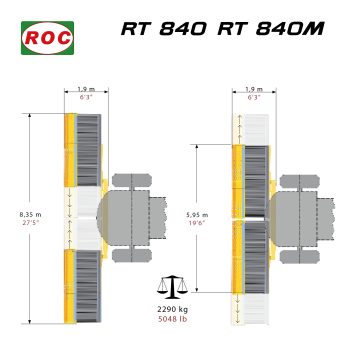

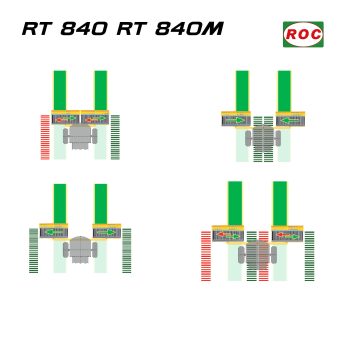

The Continuous Merger ROC RT 840 is designed to be coupled to a self-propelled windrower. It consists of 2 elements, it has a variable working width from 5,95 m (19′ 6”) to 8,35 m (27′ 5”) thanks to a double hydraulic rocker arm system that allows to change the distance between the two pick-ups, even during work. When the pick-ups are joined, it can unload one belt on the right and one on the left, or both belts on the right or on the left, whereas when the pick-ups are separated, it can unload the crop in the middle, or one belt on the right and one in the middle, or one on the left and one in the middle or even on both sides.

It is equipped as standard with:

– 6 bar pick-up

– 8 wheels placed in tandem with spring suspension and electrical adjustment

– cover kit for belt for 2 elements

– kit wider strips for hard crop (+ tine wear)

It can’t be folded up for road transport.