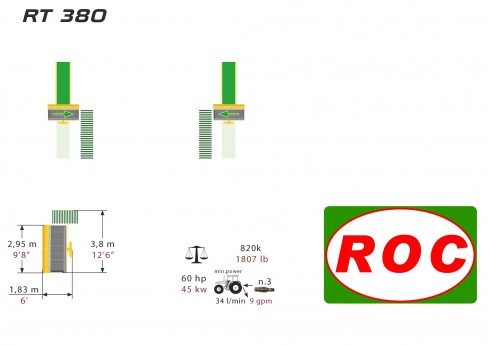

RT 380

Continuous merger ROC RT 380 represents the symbol of a revolutionary raking system. The main difference compared to traditional rakes is represented by both the pick-up system and by the working position of the merger as to the tractor. Firstly, ROC RT 380 lifts the crop in order then to transport it on a conveyor belt, whereas traditional rakes drag the crop on the ground up to the windrow. Secondly, unlike traditional rakes ROC RT 380 can be fastened both on the front and on the back of the tractor, driving it in this latter case with inverted drive. These differences lead to:

- no stripping of crop leaves and no product contamination due to tractor wheels. The RT 380 is the only merger of the RT series that can be fastened on the front or on the back of the tractor, so that crop is picked-up before that tractor wheels run over it. This is extremely important if you have to pick-up crop which is evenly distributed on the ground and if you work with a rake less than 4 m in width. The width of tractor wheels indeed can easily reach 25 – 30% of the rake width, which means that they run over the same percentage of hay on the ground;

- easy working conditions even in very small fields. By using the merger frontally, it is easy indeed to control the working area and to reduce the operator’s weariness;

- less stripping of hay and higher quality. Owing to sun drying little alfalfa stalks, which support leaves, become indeed extremely fragile. If you pick-up crop using traditional rotary-rakes and especially in the absence of dew, little stalks are more subject to breaking. This causes the loss of leaves and the consequent loss of important proteins for animal feeding. On the opposite, by using ROC system the crop is lifted and put gently on the belt in order to be transported and deposited centrally without any damage. Moreover, our tests shown that there is a smaller quantity of earth and pebbles inside the windrow, which enables to reach an incomparable product quality;

- lower product losses. In presence of wheel-tracks or holes, during crop dragging traditional rakes tend to leave on the ground a part of product. On the opposite, with our revolutionary continuous merger the crop is lifted on a belt and it is not dragged on the ground as it usually happens with traditional rakes;

- less damages to fresh growth of crop. Under normal conditions, already after 2 or 3 days from harvesting some kinds of crop like alfalfa produce fresh growth made up of small stalks and some leaves. Under these conditions, rotary-rakes tend often to break the small stalks, causing a delay in growth and therefore in harvesting, which means at the end of the season a delay of some weeks in the case of 5 crop cuttings.

The machine offers moreover the following further advantages:

the chance to increase the working hours amount of the machine, which moreover enables to reduce the number of machines at work. Compared to traditional rakes, thanks to its very soft way of handling the crop the merger series RT allows to extend considerably the working time, up to doubling the daily working hours in the most cases. This system has several advantages. Firstly, it allows to work using not only less mergers but also less tractors, reducing in this way the number of workers involved in operations of such a short length of time. A further advantage is represented by the chance of avoiding night work, more expensive and not welcomed by workers. By concentrating the work during daytime the product is dryer and evener, which is a hardly achievable result if you rake a product wet by dew.